Deadline: December 5, 2023

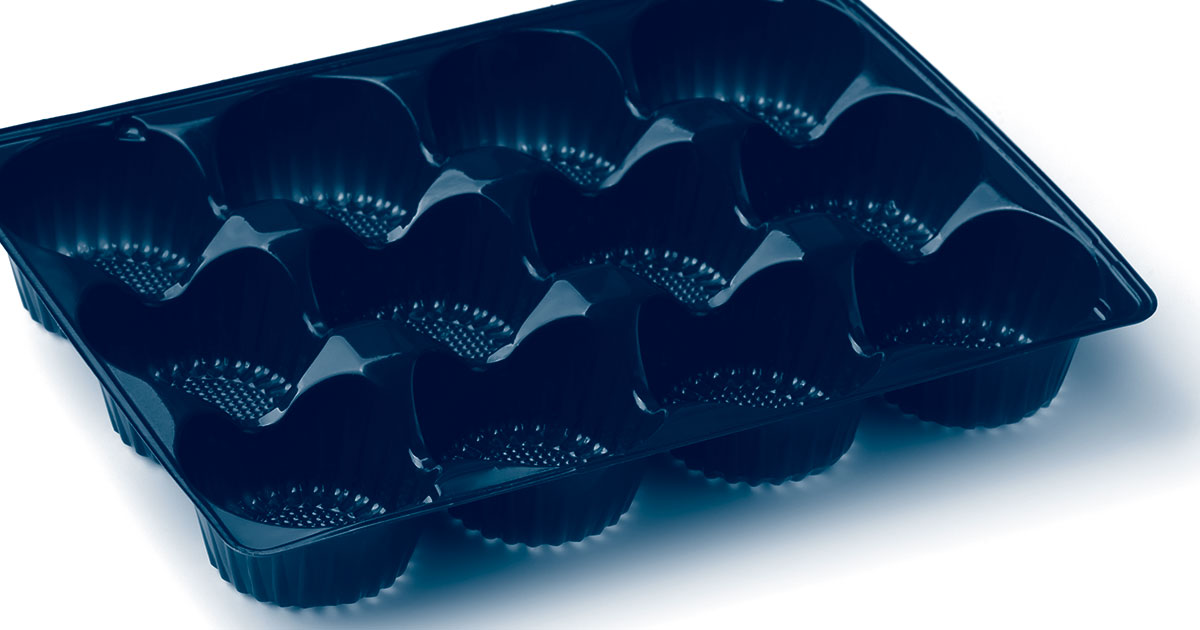

Mondelez, the global snack and cookie company, seeks to optimize the design and manufacturing of their plastic trays through simulation. Through this project, the company hopes to identify modeling partners to collaborate with for improved design and optimization of thermoformed trays.

From airplanes to automobiles, logistics to rockets, designers and engineers are constantly on the lookout for opportunities to remove weight while preserving safety and performance. By doing so, fewer materials are needed, reducing production and fuel costs without negative impacts elsewhere in the operation. Mondelez, a Fortune 500 company, also wants to reduce unnecessary weight by optimizing the plastic trays that protect their products from harm during transit.

Mondelez intends to identify collaboration partners with the ability to simulate and optimize all aspects of tray design including size, shape, structure and materials used. Through this process, Mondelez wants to design new trays that meet or exceed current performance while also requiring less plastic to construct.

Expertise and insights from across the packaging and plastics industries are welcome. Furthermore, any industries impacted by lightweighting efforts including automotive, aerospace, and logistics are also encouraged to respond as there is interest in bringing outside perspectives to this project.

Mondelez is interested in connecting with design firms, simulation platform providers, and other organizations with an interest and ability to optimize components via simulation software. Platforms with AI/ML-supported capabilities are highly desirable.

Regardless of industry or specialization, organizations able to demonstrate the successful transition from simulation to real-world validation of product performance are of primary interest.

Review of submissions will take place in December 2023 with direct engagement beginning in January 2024. During direct engagement, Mondelez will provide additional details regarding tray dimensions, materials, and desired performance metrics. Ideally, the virtual models will generate new physical prototypes for testing prior to the end of 2024.

The goal of this sprint is to facilitate contact and interactions between the Sprint sponsor and commercial entities (including Start-ups), technology developers or research organization/university in this space.

Solvers submitting an Entry are encouraged to highlight capabilities in their Submission that meet criteria including:

- Technology Overview

- Examples of previous simulation work:

- Material(s) simulated

- Sizes/Shapes simulated

- Parameter(s) optimized

- Customization options

- Availability of AI/ML performance

- Examples of transition from simulation to real-world product(s)

- Ability to demonstrate platform performance

- Directly through in-house manufacturing OR

- Indirectly through 3rd party collaboration

- Collaboration process:

- On-premise installation OR

- Cloud-based access OR

- Facilitated discussions with remote experts

- Technical maturity